Guide to Magnetic Separation Technology: Transforming Mineral Processing Operations

Magnetic separation technology is widely used in mineral processing to separate valuable magnetic minerals (like magnetite or hematite) from non-magnetic gangue material. By applying magnetic fields, crushers and separators can concentrate ores, reduce waste, and improve the purity of output materials. This technique is essential in mining operations that aim to maximize yield and reduce downstream processing costs.

In recent years, advances in magnetic separation methods—such as high gradient magnetic separators (HGMS), superconducting magnets, and AI-assisted control systems—have significantly improved performance. The focus has shifted toward achieving finer separations, reducing energy usage, and recovering minerals from previously uneconomical sources. These innovations are reshaping how modern mineral operations choose and use magnetic separators.

Importance of Magnetic Separation in Mineral Processing

-

Enhances the grade and quality of mineral concentrates by removing non-magnetic impurities.

-

Reduces the volume of material requiring energy-intensive downstream processing (like flotation or chemical treatment).

-

Lowers operational costs and energy consumption, especially when using efficient separator designs and automation.

-

Offers environmental benefits by minimizing chemical use, reducing water consumption, and recovering valuable minerals from tailings.

Types of Magnetic Separation Methods

| Method | Description | Main Use |

|---|---|---|

| Low-Intensity Magnetic Separation (LIMS) | Uses relatively weak magnetic fields to separate strongly magnetic minerals, such as magnetite. | Initial separation stages, coarse magnetic minerals. |

| High-Intensity Magnetic Separation (HIMS) | Applies stronger magnetic fields to extract weakly magnetic minerals like hematite. | Purification, weakly magnetic ores. |

| High Gradient Magnetic Separation (HGMS) | Generates high magnetic field gradients to capture very fine magnetic particles. | Fine mineral recovery, handling complex ore matrices. |

| Dry Magnetic Separation | Separation without involving water—useful in dry conditions. | Arid regions, handling dry ore. |

| Wet Drum Magnetic Separators | Use water medium and rotating drums for separation. | Fine particle separation, wet ore processing. |

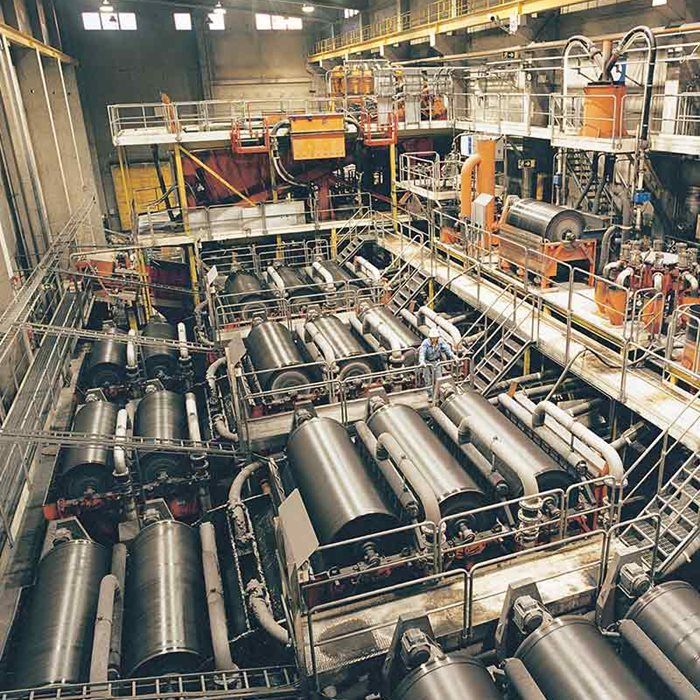

Key Components & Working Process

-

Ore Preparation: Crushing and grinding to liberate magnetic and non-magnetic components.

-

Magnetic Field Source: Permanent magnets or electromagnets generate the field required for separation.

-

Separator Unit Types: Drum separators, pulleys, belt or disc separators for various scales and particle sizes.

-

Feed Handling & Particle Size Control: Particle size, moisture content, and feed rate all affect efficiency.

-

Concentrate & Tailings Recovery: Magnetic feed is collected as concentrate; non-magnetic material becomes tailings

Best Practices for Selecting Magnetic Separation Equipment

-

Match separator type to ore’s magnetic properties (strong, weak, paramagnetic).

-

Consider particle size range: fine particles typically require HGMS or wet drum methods.

-

Evaluate magnetic field strength and gradient required for separation.

-

Assess capacity needs: throughput, duty cycle, and continuous vs batch operation.

-

Check energy efficiency and power consumption of magnets and drive systems.

-

Factor in maintenance, durability, and availability of spare parts.

-

Ensure environmental compliance: water usage, waste handling, emissions.

Recent Innovations & Trends

-

Use of superconducting magnets for stronger field strengths with lower operational energy.

-

Automation and real-time monitoring (AI / sensors) adjusting separator settings based on feed composition.

-

Recovery of valuable minerals from tailings and waste streams—resource recovery becoming more viable.

-

Hybrid separation methods combining magnetic, density, and gravity separation to improve yields.

-

Increased application of dry separators and recycling of water to reduce environmental impact.

Environmental & Safety Considerations

-

Reduce water consumption in wet separation; recycle and treat process water.

-

Minimize energy use by selecting efficient separators and optimizing field strengths.

-

Handle tailings and magnetic concentrates safely to avoid environmental contamination.

-

Comply with regulations regarding dust, noise, and emissions in mining areas.

-

Ensure operator safety around strong magnetic fields and high-intensity equipment.

FAQs

Q1. What is the difference between low-intensity and high-intensity magnetic separation?

Low-intensity separates strongly magnetic minerals at weaker fields; high-intensity is needed for weakly magnetic or paramagnetic minerals needing stronger magnetic force.

Q2. Can magnetic separation recover minerals from tailings?

Yes; advanced separators (like HGMS or superconducting) are increasingly used for recovering valuable minerals from tailings that were previously considered waste.

Q3. Is wet magnetic separation always better than dry?

Not always. Wet methods often achieve finer separation and handle small particles well, but dry methods are better in water-scarce or arid areas and reduce water handling issues.

Q4. How does particle size affect magnetic separation efficiency?

Smaller and finer particles are harder to capture unless the separator has high gradient fields and efficient feed preparation; coarse particles are easier but may require less intense equipment.

Q5. What types of minerals are typically processed with magnetic separation?

Common examples include magnetite, hematite, ilmenite, some rare earth minerals, and minerals with magnetic or paramagnetic characteristics.

Conclusion

Magnetic separation technology plays a vital role in modern mineral processing, offering methods to efficiently and sustainably separate magnetic from non-magnetic materials. By choosing the right method—LIMS, HIMS, HGMS, wet or dry separators—and aligning equipment with mineral properties, operations can improve yield, reduce waste, and lower environmental impact. With ongoing innovations such as superconducting magnets, automation, and tailings recovery, magnetic separation is increasingly enabling higher efficiency and sustainability in mineral extraction.