Quantum Device Manufacturing Guide: Explanation, Challenges, Applications, and Resources

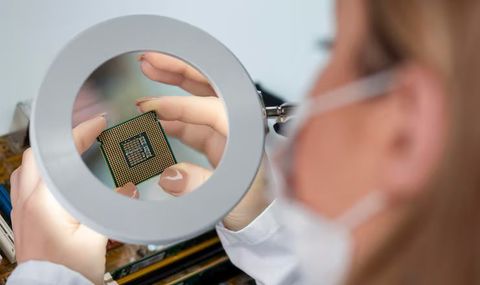

Quantum device manufacturing refers to the process of designing, fabricating, assembling, and validating hardware that operates using principles of quantum mechanics. These devices include quantum processors, sensors, communication components, and experimental platforms that rely on quantum states such as superposition and entanglement.

The topic exists because classical electronics are approaching physical and performance limits. As traditional semiconductor scaling slows, researchers and engineers have turned to quantum phenomena to enable new capabilities in computation, sensing, and secure communication. Manufacturing is the bridge between theoretical quantum science and practical, usable devices.

Unlike conventional electronics, quantum devices are extremely sensitive to environmental factors such as temperature, electromagnetic noise, and material impurities. This sensitivity makes manufacturing not only a technical process but also a precision-driven discipline that combines physics, materials science, nanofabrication, and systems engineering.

Why Quantum Device Manufacturing Matters Today

Quantum device manufacturing matters because it underpins the transition of quantum research from laboratories into real-world applications. Without reliable manufacturing methods, quantum technologies remain experimental and limited in scale.

This field affects multiple groups:

-

Researchers developing next-generation computing systems

-

Industries seeking advanced simulation and optimization tools

-

Governments investing in secure communication and sensing

-

Universities and labs advancing fundamental physics

-

Infrastructure planners preparing for future technologies

Key problems it helps address include:

-

Limits of classical computing performance

-

Difficulty simulating complex physical and chemical systems

-

Need for ultra-sensitive measurement and detection tools

-

Demand for secure data transmission methods

| Area | Role of Quantum Devices |

|---|---|

| Computing | New problem-solving approaches |

| Sensing | High-precision measurements |

| Communication | Enhanced security principles |

| Research | Exploration of quantum phenomena |

| Materials science | Study of complex interactions |

By enabling scalable and repeatable production, quantum device manufacturing supports the broader ecosystem needed for quantum technologies to mature.

Core Concepts Behind Quantum Device Manufacturing

At its foundation, quantum device manufacturing combines established fabrication techniques with new requirements driven by quantum behavior.

Core concepts include:

-

Control of quantum states at very small scales

-

Use of specialized materials with low noise properties

-

Fabrication at nanometer and atomic levels

-

Integration of devices with cryogenic and vacuum systems

-

Extensive testing to verify quantum performance

| Concept | Why It Matters |

|---|---|

| Material purity | Reduces decoherence |

| Nanofabrication | Enables precise structures |

| Isolation | Preserves quantum states |

| Calibration | Ensures reliable behavior |

| Repeatability | Supports scaling |

Manufacturing processes must maintain extreme consistency, as small defects can disrupt quantum behavior and reduce device usefulness.

Manufacturing Approaches and Device Types

Quantum devices are built using different physical platforms, each with its own manufacturing requirements.

Common approaches include:

-

Superconducting circuits fabricated on silicon or sapphire

-

Trapped ion systems using electromagnetic fields

-

Photonic quantum devices using optical components

-

Semiconductor-based quantum dots

-

Neutral atom arrays assembled with laser control

| Device Type | Manufacturing Focus |

|---|---|

| Superconducting | Thin-film deposition and patterning |

| Trapped ions | Precision electrode fabrication |

| Photonic | Waveguide and optical alignment |

| Quantum dots | Semiconductor nanostructures |

| Neutral atoms | Vacuum and laser stability |

Each approach requires specialized equipment and expertise, making manufacturing diversity a defining characteristic of the field.

Key Challenges in Quantum Device Manufacturing

Manufacturing quantum devices presents challenges beyond those found in conventional electronics.

Major challenges include:

-

Maintaining coherence during and after fabrication

-

Controlling defects at atomic scales

-

Achieving uniformity across multiple devices

-

Integrating quantum components with classical control systems

-

Scaling production while preserving performance

| Challenge | Practical Impact |

|---|---|

| Decoherence | Limits device usefulness |

| Material defects | Reduce reliability |

| Process variability | Hinders scaling |

| System integration | Increases complexity |

| Environmental sensitivity | Requires strict controls |

Addressing these challenges requires close collaboration between physicists, engineers, and materials scientists, as well as continuous refinement of manufacturing techniques.

Recent Updates and Industry Trends in 2024–2025

The past year has seen notable progress in quantum device manufacturing, reflecting increased investment and collaboration.

Key developments include:

-

Early 2024: Improved fabrication techniques for superconducting devices

-

Mid 2024: Greater use of automated calibration and testing

-

Late 2024: Advances in hybrid quantum-classical system integration

-

Early 2025: Focus on repeatability and yield improvement

| Period | Update | Significance |

|---|---|---|

| 2024 | Process refinement | Higher device consistency |

| 2024 | Automation | Reduced manual variability |

| 2024 | Hybrid systems | Better practical integration |

| 2025 | Yield focus | Steps toward scalability |

These updates suggest a shift from purely experimental production toward more standardized manufacturing practices.

Applications Enabled by Quantum Device Manufacturing

Reliable manufacturing expands the range of applications where quantum devices can be explored and tested.

Key application areas include:

-

Quantum computing research and prototypes

-

Precision sensing in physics and materials science

-

Secure communication experiments

-

Fundamental studies of quantum behavior

-

Advanced metrology and timing systems

| Application Area | Manufacturing Role |

|---|---|

| Computing | Enables multi-qubit devices |

| Sensing | Improves measurement stability |

| Communication | Supports photonic components |

| Research | Provides reproducible platforms |

| Metrology | Enhances precision standards |

While many applications remain in development, manufacturing progress is essential for translating theory into practice.

Laws, Policies, and Government Influence

Quantum device manufacturing is influenced by a mix of science policy, technology strategy, and regulatory frameworks.

Relevant policy areas include:

-

National quantum research programs

-

Export control and technology oversight

-

Research funding and infrastructure support

-

Safety and laboratory standards

-

Data security and critical technology protection

Governments in many countries have launched quantum initiatives to support research, fabrication facilities, and workforce development. These programs shape how manufacturing capabilities are developed and shared.

Policy considerations also influence collaboration, as quantum technologies are often viewed as strategically important.

Tools and Resources Supporting Quantum Manufacturing

A wide range of tools and resources support quantum device manufacturing, spanning design, fabrication, and testing.

Helpful resources include:

-

Nanofabrication process design tools

-

Simulation software for quantum behavior

-

Cleanroom fabrication guidelines

-

Measurement and characterization frameworks

-

Open research publications and datasets

| Resource Type | Purpose |

|---|---|

| Simulation tools | Predict device behavior |

| Fabrication guides | Standardize processes |

| Measurement tools | Verify quantum properties |

| Research literature | Share findings |

| Technical standards | Align practices |

These resources help reduce uncertainty and improve reproducibility across different research and manufacturing environments.

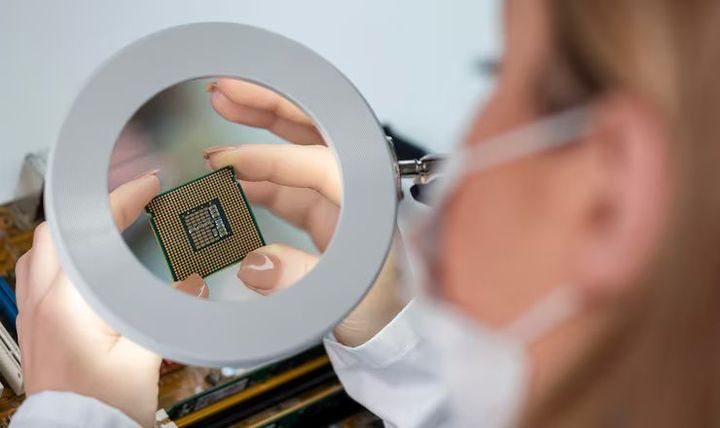

Quality Control and Validation Practices

Quality control is central to quantum device manufacturing because performance cannot be inferred solely from physical appearance.

Validation practices often include:

-

Repeated low-temperature testing

-

Noise and coherence measurements

-

Calibration against reference devices

-

Statistical analysis of device behavior

-

Long-term stability observation

Such practices ensure that devices meet expected performance benchmarks and provide meaningful experimental results.

Environmental and Infrastructure Requirements

Quantum device manufacturing requires controlled environments that go beyond standard industrial settings.

Common requirements include:

-

Cleanroom facilities

-

Cryogenic systems for low-temperature operation

-

Vibration and noise isolation

-

Stable power and electromagnetic shielding

-

High-precision alignment tools

These infrastructure needs contribute to the complexity and specialized nature of quantum manufacturing facilities.

Frequently Asked Questions

What makes quantum device manufacturing different from traditional electronics?

Quantum devices rely on fragile quantum states, requiring far stricter control of materials, environments, and fabrication precision.

Why is scaling quantum devices difficult?

Small variations in materials or processes can disrupt quantum behavior, making consistent large-scale production challenging.

Are quantum devices already used outside research labs?

Most quantum devices are still in research or pilot stages, with manufacturing focused on experimental and early-stage platforms.

How important are materials in quantum manufacturing?

Material purity and structure are critical, as defects can cause loss of quantum coherence and reduced performance.

Do regulations limit quantum device development?

Regulations mainly influence research funding, collaboration, and technology oversight rather than day-to-day manufacturing steps.

Conclusion

Quantum device manufacturing is a crucial foundation for the advancement of quantum technologies. By translating abstract quantum principles into physical hardware, manufacturing enables experimentation, validation, and gradual progress toward practical applications.

The field is defined by precision, interdisciplinary collaboration, and continuous innovation. While challenges related to scaling, consistency, and environmental sensitivity remain, recent developments show steady progress toward more reliable and repeatable manufacturing approaches.

As research, policy support, and technical expertise continue to grow, quantum device manufacturing will play an increasingly important role in shaping the future of computing, sensing, and secure communication.