Relay Testing Equipment Guide: Explore Functions, Uses, and Key Insights

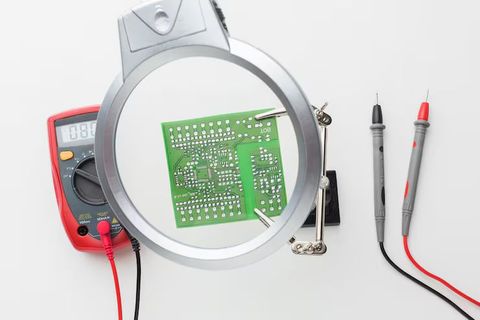

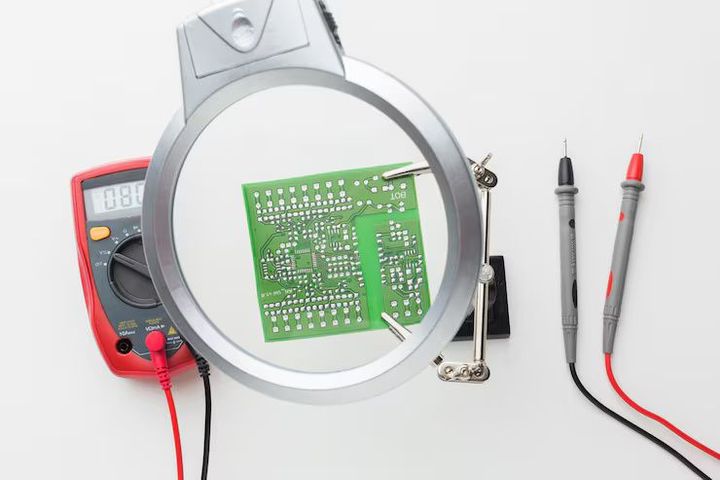

Relay testing equipment refers to specialized instruments used to verify the performance, accuracy, and reliability of protective relays in electrical systems. Protective relays are critical components that monitor electrical conditions and trigger corrective actions when faults such as overloads, short circuits, or voltage irregularities occur. Relay testing equipment exists to ensure these relays function correctly under real-world operating conditions.

As electrical networks became more complex, manual inspection alone was no longer sufficient to validate relay behavior. Power generation plants, substations, transmission networks, and industrial facilities required reliable ways to simulate electrical events and confirm relay responses. Relay testing equipment was developed to address this need by providing controlled testing environments that replicate actual fault scenarios.

These systems are used during commissioning, routine maintenance, troubleshooting, and compliance checks. Their role is not limited to identifying faults but also to confirming coordination between multiple protection devices across an electrical network.

Why Relay Testing Equipment Matters Today

Relay testing equipment plays a vital role in modern power systems where reliability, safety, and uptime are critical. It affects utilities, industrial operators, infrastructure providers, engineers, and regulators.

Several factors highlight its importance:

-

Growing demand for uninterrupted power supply

-

Expansion of renewable energy and smart grids

-

Increasing system automation and digital protection

-

Higher safety and compliance expectations

| Power System Challenge | Role of Relay Testing Equipment |

|---|---|

| System faults | Verification of protection response |

| Network complexity | Coordination validation |

| Aging infrastructure | Preventive assessment |

| Safety requirements | Risk reduction |

| Regulatory audits | Performance documentation |

Without proper relay testing, faults may go undetected or protection systems may operate incorrectly, leading to equipment damage, safety hazards, or widespread outages.

Core Functions of Relay Testing Equipment

Relay testing equipment is designed to perform multiple technical functions that help evaluate relay behavior accurately. These functions vary depending on the type of relay and the complexity of the system.

Key functions include:

-

Injection of current and voltage signals

-

Simulation of fault conditions

-

Measurement of response time and accuracy

-

Verification of logic and communication signals

-

Assessment of coordination between relays

| Function | Purpose |

|---|---|

| Current injection | Test overcurrent response |

| Voltage simulation | Validate voltage protection |

| Timing analysis | Measure operating speed |

| Logic testing | Check relay decision-making |

| Communication checks | Verify digital signaling |

These functions allow engineers to confirm that relays respond within expected parameters and interact correctly with other protection devices.

Types of Relay Testing Equipment

Relay testing equipment can be broadly categorized based on capability, application, and level of automation.

Common types include:

-

Secondary injection test sets

-

Primary injection test systems

-

Automated relay test platforms

-

Portable field testing units

-

Advanced digital relay analyzers

| Type | Typical Use Case |

|---|---|

| Secondary injection | Routine relay verification |

| Primary injection | End-to-end system testing |

| Automated platforms | Complex protection schemes |

| Portable units | On-site field testing |

| Digital analyzers | Intelligent electronic devices |

Each type supports different testing objectives, from basic functional checks to comprehensive system validation.

Practical Uses Across Industries

Relay testing equipment is used in various sectors where electrical protection is essential. Its application goes beyond power utilities and extends into multiple industrial environments.

Common application areas include:

-

Power generation facilities

-

Electrical substations and transmission lines

-

Manufacturing plants

-

Transportation infrastructure

-

Data centers and critical facilities

| Industry | Application |

|---|---|

| Power utilities | Grid protection validation |

| Manufacturing | Equipment safety assurance |

| Rail and transit | Traction system protection |

| Data centers | Power continuity testing |

| Oil and gas | Hazard prevention |

In each case, relay testing equipment supports system reliability and helps prevent costly or dangerous failures.

Recent Updates and Industry Trends in 2024–2025

Over the past year, relay testing equipment has evolved alongside advancements in power systems and digital technologies.

Notable trends include:

-

Early 2024: Increased focus on testing digital and numerical relays

-

Mid 2024: Wider adoption of automated testing workflows

-

Late 2024: Integration with substation communication standards

-

Early 2025: Enhanced cybersecurity awareness in protection testing

| Period | Update | Impact |

|---|---|---|

| 2024 | Digital relay focus | Improved accuracy |

| 2024 | Automation | Reduced manual effort |

| 2024 | Communication testing | Interoperability checks |

| 2025 | Cybersecurity | Secure protection systems |

These developments reflect the shift toward smarter, more interconnected electrical networks that require advanced testing approaches.

Laws, Standards, and Policy Influence

Relay testing equipment use is influenced by electrical standards, safety regulations, and grid codes that govern power system operation. These frameworks define acceptable testing practices and performance criteria.

Common regulatory influences include:

-

Electrical safety regulations

-

Power system protection standards

-

Grid reliability guidelines

-

Occupational safety rules

-

Government infrastructure programs

Standards bodies and regulators often require documented testing procedures to ensure that protective relays operate correctly. While regulations may vary by region, the underlying objective remains consistent: to ensure safe, reliable electrical systems.

Tools and Resources Supporting Relay Testing

A range of tools and resources support the effective use of relay testing equipment and related processes.

Helpful resources include:

-

Relay setting calculation guides

-

Protection coordination charts

-

Testing procedure templates

-

Fault simulation reference tables

-

Training and reference manuals

| Resource Type | Practical Value |

|---|---|

| Calculation guides | Accurate relay settings |

| Coordination charts | System selectivity |

| Procedure templates | Consistent testing |

| Simulation tables | Fault scenario planning |

| Reference manuals | Knowledge support |

These resources help engineers conduct structured, repeatable, and reliable testing activities.

Key Operational Considerations

When working with relay testing equipment, several practical considerations influence testing accuracy and safety.

Important factors include:

-

Correct interpretation of relay settings

-

Proper isolation of equipment during tests

-

Accurate calibration of test instruments

-

Clear documentation of results

-

Coordination with system operators

Attention to these aspects ensures that testing outcomes reflect real system behavior and support informed decisions.

Frequently Asked Questions

What is relay testing equipment used for?

It is used to verify the correct operation of protective relays by simulating electrical conditions and faults.

Who typically uses relay testing equipment?

Electrical engineers, utility technicians, maintenance teams, and commissioning specialists commonly use it.

Is relay testing required for modern digital relays?

Yes, digital relays still require testing to confirm logic, timing, and communication performance.

How often should relay testing be performed?

Testing frequency depends on system criticality, regulatory requirements, and maintenance strategies.

Can relay testing equipment support communication-based protection?

Yes, modern systems can test signaling and communication-based protection schemes.

Conclusion

Relay testing equipment is an essential part of maintaining safe, reliable, and efficient electrical systems. By enabling accurate simulation of operating conditions and faults, it helps verify that protective relays perform as intended.

As power systems continue to evolve with digital technologies and renewable integration, relay testing practices are also advancing. Understanding the functions, uses, and regulatory context of relay testing equipment supports better system performance, risk reduction, and long-term infrastructure resilience.