Custom OEM Assembly Manufacturing Overview: Workflow, Components, and Practical Knowledge

Custom OEM assembly manufacturing refers to the process where original equipment components are assembled according to specific design, performance, and integration requirements defined by another organization. The focus is on assembling parts into finished or semi-finished products that meet predefined technical and quality standards.

This manufacturing model exists because many industries require specialized assemblies that are not efficiently produced through standardized mass manufacturing alone. Products such as industrial equipment, electronics, medical devices, and automotive subsystems often need customized configurations, precise tolerances, and controlled assembly environments.

Custom OEM assembly manufacturing bridges the gap between component production and final product integration. It combines engineering documentation, process planning, material handling, and quality control into a coordinated workflow that supports reliable and repeatable outcomes.

Why Custom OEM Assembly Manufacturing Matters Today

Custom OEM assembly manufacturing plays an important role in modern supply chains as products become more complex and specialized. Many industries rely on modular designs, where individual parts are sourced separately and assembled into tailored solutions.

This topic matters to:

-

Manufacturing planners managing complex product variants

-

Engineers responsible for design-to-production alignment

-

Quality teams ensuring compliance and reliability

-

Supply chain coordinators handling multi-source components

The key problems it helps solve include:

-

Managing complexity in multi-component products

-

Reducing production errors during assembly

-

Ensuring consistent quality across customized configurations

-

Supporting faster transitions from design to production

| Manufacturing Challenge | How Custom OEM Assembly Helps |

|---|---|

| Complex product designs | Structured assembly workflows |

| Multiple component sources | Coordinated integration |

| Quality variability | Standardized assembly checks |

| Frequent design updates | Flexible process planning |

As industries adopt advanced technologies and customized equipment, the importance of structured OEM assembly processes continues to grow.

Core Workflow in Custom OEM Assembly Manufacturing

The workflow in custom OEM assembly manufacturing is designed to convert design requirements into physical assemblies in a controlled and repeatable way. While workflows vary by industry, most follow a similar structure.

Design and Documentation Review

The process begins with a detailed review of technical documentation.

Key inputs include:

-

Engineering drawings and specifications

-

Bills of materials

-

Assembly instructions

-

Quality and testing requirements

This step ensures that all stakeholders share a common understanding of product expectations.

Process Planning and Layout Design

Process planning translates design intent into assembly steps.

Activities include:

-

Defining assembly sequences

-

Selecting tools and fixtures

-

Designing workstation layouts

-

Identifying inspection points

Good planning reduces rework and improves efficiency.

Component Preparation and Kitting

Before assembly begins, components are prepared and organized.

Common practices:

-

Incoming inspection of parts

-

Sorting and labeling components

-

Creating assembly kits per unit or batch

| Preparation Step | Purpose |

|---|---|

| Inspection | Verify component quality |

| Kitting | Reduce assembly delays |

| Labeling | Improve traceability |

Proper preparation supports smooth assembly flow.

Assembly Operations

Assembly operations involve joining, fastening, aligning, and integrating components.

Typical activities include:

-

Mechanical fastening

-

Electrical connections

-

Sub-assembly integration

-

Functional alignment

Operators follow standardized work instructions to ensure consistency.

Inspection and Functional Testing

After assembly, products undergo inspection and testing.

Checks may include:

-

Visual inspection

-

Dimensional verification

-

Electrical or mechanical function tests

-

Documentation review

Testing confirms that assemblies meet defined requirements.

Packaging and Handover

The final step prepares assemblies for storage, transport, or further integration.

Tasks include:

-

Protective packaging

-

Labeling and documentation

-

Handover to logistics or next production stage

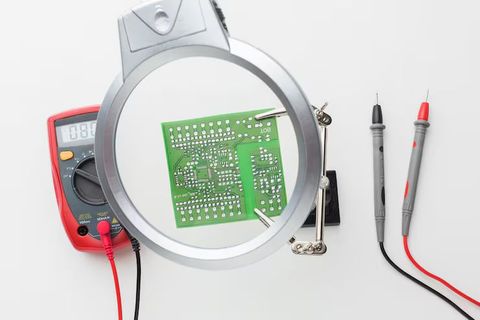

Key Components in OEM Assembly Manufacturing

Custom OEM assembly manufacturing involves a wide range of components depending on the application.

Common component categories include:

-

Mechanical parts such as housings, frames, and fasteners

-

Electrical components including wiring, connectors, and control units

-

Fluid or pneumatic elements such as hoses and valves

-

Interface components for mounting and integration

| Component Type | Role in Assembly |

|---|---|

| Mechanical | Structural integrity |

| Electrical | Power and control |

| Fluid/Pneumatic | Motion or process control |

| Interfaces | System integration |

Understanding component interactions is essential for reliable assembly outcomes.

Practical Knowledge for Effective OEM Assembly

Practical knowledge supports consistent performance in custom assembly environments.

Important considerations include:

-

Clear work instructions with visual aids

-

Controlled torque and fastening methods

-

Clean assembly conditions where required

-

Traceability of parts and processes

Operators and supervisors rely on documented procedures and training to maintain quality across different product variants.

Recent Updates and Industry Trends in 2024–2025

Over the past year, custom OEM assembly manufacturing has evolved in response to technological and operational changes.

Key developments include:

-

Early 2024: Increased use of digital work instructions and tablets

-

Mid 2024: Greater focus on traceability and data capture

-

Late 2024: Improved integration of testing within assembly lines

-

Early 2025: Expanded use of modular assembly cells

| Period | Update | Impact |

|---|---|---|

| 2024 | Digital documentation | Reduced errors |

| 2024 | Enhanced traceability | Better quality tracking |

| 2024 | Integrated testing | Faster validation |

| 2025 | Modular cells | Flexible production |

These trends reflect a shift toward smarter and more adaptable assembly systems.

Quality and Risk Management Considerations

Quality management is central to custom OEM assembly manufacturing.

Common quality practices include:

-

In-process inspections

-

Standardized checklists

-

Controlled change management

-

Documentation audits

Risk management focuses on identifying potential assembly errors early and implementing preventive measures.

Laws, Regulations, and Policy Influence

Custom OEM assembly manufacturing is influenced by various regulatory frameworks, depending on industry and region.

Key regulatory areas include:

-

Product safety standards

-

Workplace health and safety rules

-

Environmental handling of materials

-

Documentation and traceability requirements

Government programs that support advanced manufacturing and skill development also influence assembly practices. Compliance with applicable laws helps ensure safe operations and reliable products.

Tools and Resources Supporting OEM Assembly Manufacturing

A range of tools and resources support planning, execution, and monitoring of assembly processes.

Useful tools and resources include:

-

Assembly process planning software

-

Digital work instruction platforms

-

Torque monitoring tools

-

Inspection and measurement devices

-

Industry standards documentation

| Tool Category | Application |

|---|---|

| Planning software | Workflow design |

| Digital instructions | Operator guidance |

| Measurement tools | Quality checks |

| Standards documents | Compliance reference |

These resources help maintain consistency and efficiency across customized assemblies.

Challenges in Custom OEM Assembly Manufacturing

Despite structured workflows, challenges remain.

Common challenges include:

-

Managing frequent design changes

-

Coordinating multiple component suppliers

-

Maintaining consistency across small batches

-

Training operators for diverse assemblies

Addressing these challenges requires strong communication, documentation, and process discipline.

Frequently Asked Questions

What does OEM assembly manufacturing involve?

It involves assembling components into products based on predefined design and quality requirements provided by another organization.

How is custom OEM assembly different from mass production?

Custom OEM assembly focuses on tailored configurations and smaller batches rather than standardized high-volume output.

Why is documentation important in OEM assembly?

Clear documentation ensures consistent assembly, quality control, and traceability.

What industries commonly use OEM assembly manufacturing?

Industries such as automotive, electronics, industrial equipment, and medical devices frequently rely on OEM assembly.

How is quality ensured during assembly?

Quality is ensured through standardized procedures, inspections, testing, and traceability systems.

Conclusion

Custom OEM assembly manufacturing is a structured approach to building specialized products from multiple components. By following defined workflows, managing components carefully, and applying quality controls, organizations achieve consistent and reliable assembly outcomes.

Recent trends show a move toward digital tools, better traceability, and flexible assembly layouts. Regulations and standards continue to shape safe and compliant practices. With the right tools, documentation, and practical knowledge, custom OEM assembly manufacturing supports modern industries that demand precision, adaptability, and reliability.